Description

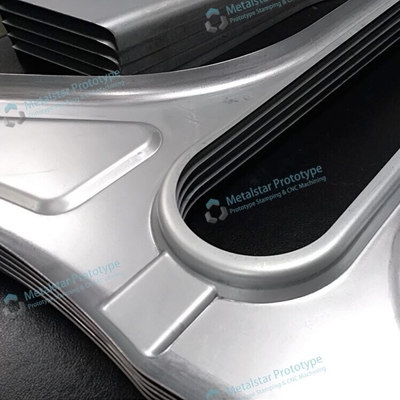

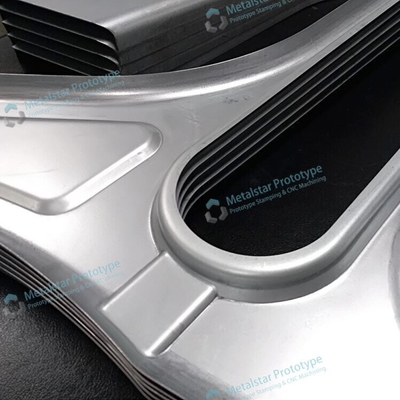

| Material Type: | 1.2mm High Strength Low Carbon Steel | Production Method: | Rapid Sheet Metal Stamping |

|---|---|---|---|

| Application: | Rapid Prototype Sheet Metal Fabrication | Fabrication Precision: | +/- 0.50mm |

| Services: | Prototyping, Customized Fabrication | Rapid Or Regular Process: | Rapid Process |

| Highlight: |

HSLAS sheet metal stamping,HSLAS fast prototype,1.20mm Vehicles Sheet Metal Stamping |

||

RAW MATERIAL INFORMATION OF PROTOTYPE STAMPING

H300LAD is a low alloy high-strength hot-dip galvanized carbon steel, coated with pure zinc coating, used for cold forming, standard Q/BQB 420-2003. This is a often used raw material for fast prototype making in vehicle industries like bicycle, motorcyle,autombile etc.

H-high-strength cold formed steel with a lower yield strength limit of 300, L-low alloy, D-hot-dip galvanized, Z-pure zinc, with a normal zinc flower surface structure.

| Steel Material Properties | |||||||||

| Material Grade/Description | Chemical Composition

(weight %) |

Tensile strength (Mpa) |

Yield strength (Mpa) |

Elongation | Remarks | ||||

| (C) | (P) | (Mn) | (S) | (Si) | |||||

| Q/BQB 420-2003 H300LAD+Z. +ZF | <=0.11 | ≤0.025 | ≤1.0 | ≤0.025 | ≤0.50 | 380-480 | 300-380 | ≥23% | Company standard of China Bao Steel |

This type of steel is a product of Bao-steel, with a general yield strength of 300-380 and a tensile strength of 380-480. The elongation after fracture is not less than 23%, and the bending center diameter at nominal thickness is 2A, where a is the thickness. Surface treatment usually involves chromate passivation and oil coating to prevent white rust during transportation and storage.

For more information about similar raw materials or options for rapid prototype stamping, please contact us by phone call or by send Email at metalstar@outlook.com. Thank you!